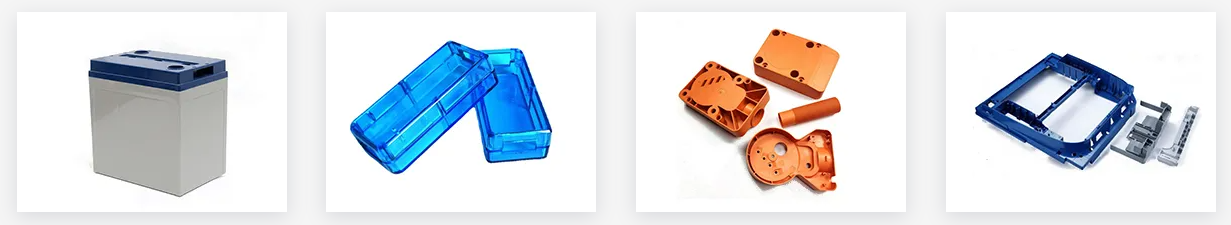

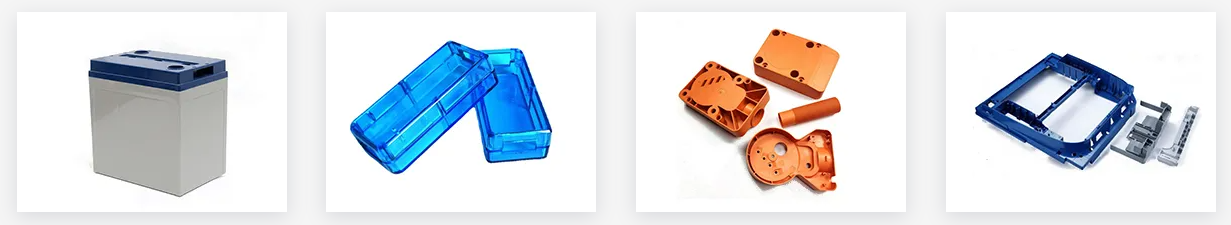

Injection Molding Service

At Shenzhen 3D Innovate we specialize in high-quality custom injection molding and mold tool making.Injection molding is by far the industry’s most common way to manufacture plastic parts, especially when making larger quantities.We provide custom molding for 50 to 100,000+ injection-molded parts as well as a wide range of other manufacturing and finishing services to complete your project.

Advantages of Injection Molding

Injection molding is an excellent option for the large-scale production of plastic parts and components. After all, there’s a reason why so many high-tech companies worldwide use it for producing parts.

Advantages of Injection Molding with Shenzhen 3D Innovate

Why should you choose us as your injection molding supplier? Here are the top 3 reasons:

Experienced Engineers

Our injection molding engineers have rich experience after handling thousands of projects; whichever parts they come across, they can get the correct parameters immediately.

Advanced Facilities

We can make the most precise moldings using imported and top-brand local injection molding machines.

Unlimited Capacities

Full fleets of metal and plastic injection molding machines, from 10 to 1000 tons are ready for your orders without delay.

Steps to get injection molded parts

In any injection molding project, crucial decisions must be made before the molding process begins.

The workflow often goes like this:

Select the material: Material selection is the first step when preparing for injection molding. Product designers will typically consider specific injection molding materials when designing a new product. And if they are unsure, making rapid prototypes is the best way to test out different material options.

Confirm the quantity: It is crucial to discuss the proposed number of molded parts to be produced at the outset. The number of shots will determine the type of mold used: a prototype mold or a high-volume production mold.

Mold flow analysis: Injection molding mold flow analysis software provides a simulation report. The report predicts factors like part warpage and cooling channel efficiency and ultimately helps manufacturers avoid mistakes. In the event of a negative report, the design can be changed to improve the injection molding process.

Create the mold: Mold making is a specialist process. These days, molds are often made via CNC machining and EDM since these processes can quickly produce highly detailed metal molds.

Create the moldings: Once the mold is ready to go, the injection molding process can begin.